Industry experts and software

guaranteed to make your

business and your life better.

Hello and welcome to NewBOS's website.

We understand how busy you are, so we promise to efficiently help you determine if NewBOS is the right solution for you.

We also understand the difficulties you encounter in finding, training, and retaining quality resources.

You will be happy to know our software products have never missed a single day of productive work in 37 years. Read More

Jeff M. White,

Founder & Member

company with 37 years success

helping agricultural commodity

related businesses thrive.

Discover How Your Life will be Better with NewBOS

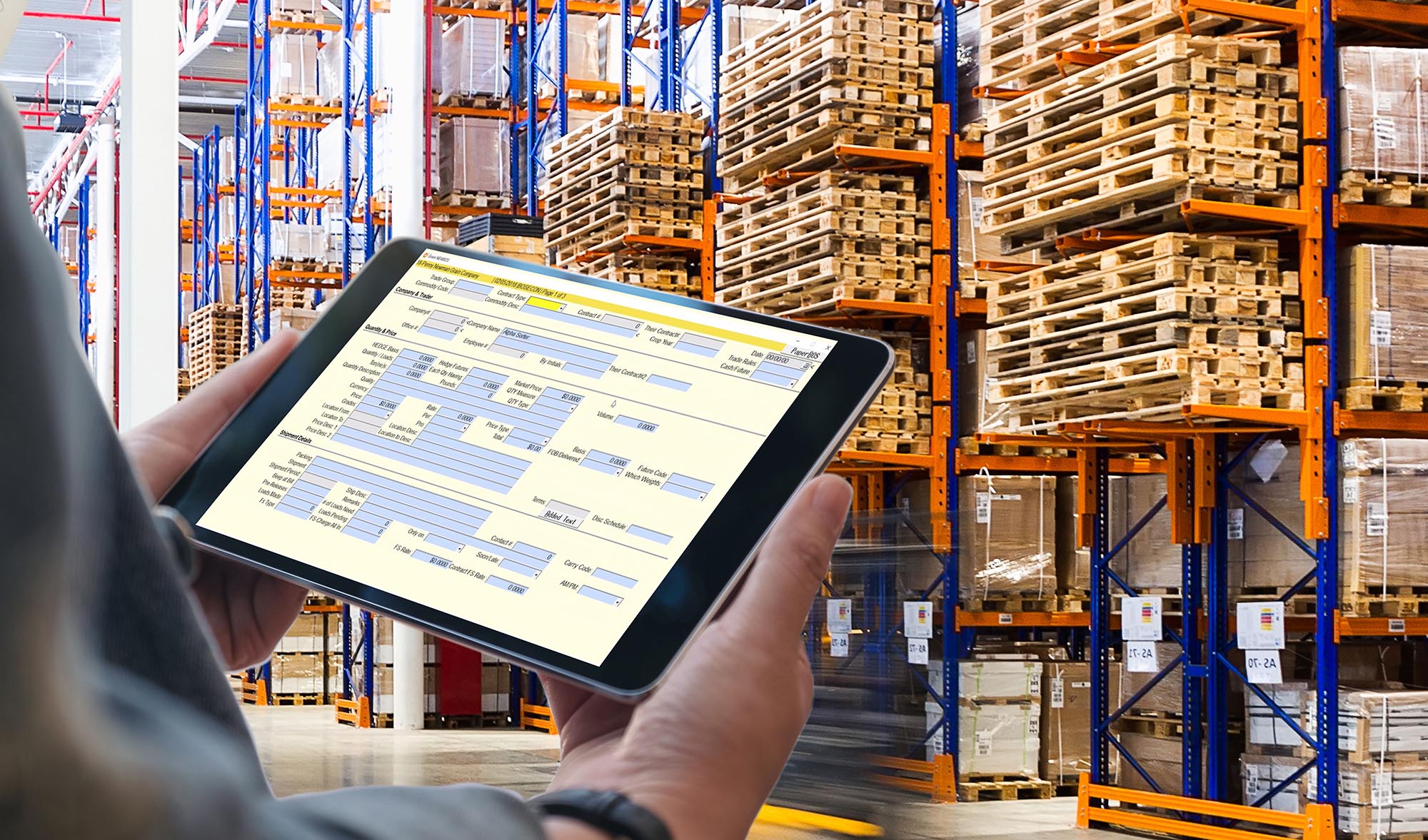

Owning and running a commodity related agri-business can be stressful, especially when using generic and disconnected software tools causing waste and duplicated efforts.

Most generic software doesn't understand the complexities your team faces every day.

If you're stressed about position risks, inaccurate financials, or lack of control, NewBOS is the solution.

Our integrated software gives you and your team confidence, efficiency, and productivity, truly offering a clear control point for your entire business.

With NewBOS, you will know your numbers and your risks daily, boosting your company's confidence and growth potential.

You will enjoy less stress and more time for fun and your family by benefiting from our decades of success in helping companies like yours.

INDUSTRY EXPERTISE:

We truly understand your industry, saving you time and money.

Your team will benefit from proven best practices which are built into our software.

Solution by your Industry

By Products / Organics /

Upcycling / Renewables

- Organics, NGMO, Conv.

- Cottonseed, Meal, Hulls

- Distillers, DDG, Canola

- Fish, Shrimp. Pumpkin

- Potato, Peanut, Tomato

- Midds, Pellets, Screenings

- Hominy, Citrus, Grease Trap

- Used Cooking Oil (UCO)

- Blood, Bone, Meat

- Call and ask about yours...

Dairy / Beef / Poultry Feed

Pet Food / Bird Seed / Fertilizer

- Premixes, Hand Adds

- Mix Forms, As Made (var.)

- Nutrients, Guarantee Tag

- Finisher, Starter, Scratches

- Blends, Standard Costing

- Sunflower, Canola, Millet

- Cheese, Whey, Milk

- Sacked, Toted, Bulk

- Call and ask about yours...

Grains / Pulses / Hay

Seeds / Commodities

- Grades, Deductions, Taxes

- Split Payments, Settlements

- Soybeans, Canola, Meals

- Flax. Millet, Sorghum. Spelt

- Buckwheat, Rye, Barley

- Oats, Safflower, Milo, Nyjer

- Chickpea/Garbanzo, Peas

- Corn. Wheat, Popcorn

- Call and ask about yours...

Transportation / Logistics

Transloading / Brokerage

- Logistics Scheduling

- Transload, Transfer, Store

- Inventory Multiple Owner

- Broker. Trailer Leases

- Dispatch Emails, Text/MMS

- Driver App, Proof of Delivery

- Fuel Cards, Advances

- Loaded/Round Trip Miles

- Upload to BulkLoads.com

- Call about your specifics...

Our fully integrated tools and industry expertise will reduce your stress and frustrations caused from using generic tools and spreadsheets.

Solution by Business Model

Trading / Brokerage

Merchandising

- Purchases, Sales, Confirms

- Basis, HTA, Flat. Indexed

- Integrated Logistics (TMS)

- Smart Risk Control (CTRM)

- Ahead/Behind Status

- Live Contract Balances

- Tons, Metric, Bushel, Lbs,

- Call for more details...

Manufacturing / Milling

Mixing / Blending / Crushing

- Mix, Ration. Formula (BOM)

- Moving, Standard Costs

- Projected Demand/Supply

- Book to Physical Process

- Inventory, Lot # Tracking

- Complex Splits, Crush

- Nutrients, Guarantees

- Call for more details...

Warehousing / Packaging

Retail Feed Store

- Barcode Pallet/Tote (WMS)

- Integrated Lots w/ Auditing

- Unlimited Sites / Areas

- Unlimited Owners / COA

- Detailed BOLs, Tickets

- Scale In/Out NTEP Cert.

- Live "On Hand" Map

- Call for more details...

Import / Export

- Vessel, Rail, Container

- Bookings, ISF, Customs

- Multi-Currency, Prepays

- Drayage and Demurrage

- On Water, Port, Emptied

- Copy/Paste Car#/Container#

- Cash Demand Projection

- Call for more details...

No Matter Your Role, your work life will improve with NewBOS, it's our promise.

Solution by your Role

Trader / Owner

Merchandiser

- With NewBOS, the stress about trading risk and financial control vanishes.

- Daily you'll have live Trading Positions and accurate Financial Statements.

- Your trader's contracts flow seamlessly into logistics for transportation execution, then automatically flow to accounting.

- Your inventory, credit, and compliance are also integrated and controlled effortlessly.

- No more spreadsheets or duplicated efforts are needed as your team benefits from NewBOS's industry specific best practices.

- No more waiting for results or uncertainty, with NewBOS you will always know all your numbers.

Logistics / Dispatcher

Transportation Manager

- Logistics is the critical glue between trading and accounting, scheduling, and planning here keeps things running smoothly.

- Our Logistics Manager tool simplifies this demanding role by providing a central hub for all planning, active loads, and load history.

- Imagine one tool managing every aspect of transportation, including inventory movements, international and direct shipments.

- You can easily link all critical controls ids such as Car#/Container#, Release#, PO#, Origin#, Destination#, together, easily.

- With NewBOS's full and automatic integration, manual updates and separate spreadsheets are eliminated, benefiting everyone.

- Traders and accounting teams receive real-time updates, minimizing repeated requests for status updates.

- You will enjoy automated email or MMS messaging, empowering more loads completed correctly with less effort.

- TruckBOS/WebBOS are our integrated apps for drivers and dispatchers outside of your team, allowing even more productivity.

- NewBOS truly is the complete logistics and transportation management (TMS/LMS) tool you've been dreaming of.

Inventory / Warehouse

Scale / Plant Manager

- End to End Inventory Control is crucial for safeguarding a company's most valuable asset.

- Our system offers real-time visibility and control from truck arrival, until it leaves, and everything in between.

- By utilizing our NTEP certified scale software, you can seamlessly track trucks, railcars, containers, pallets, and lots.

- We connect all your scales for smooth in, out, and transfer events, generating fully digital documents including scale tickets and BOL, COAs.

- With every transaction, inventory balances update instantly, complete with a visual facility map by storage location or bin.

- Automated daily accounting reconciliation ensures accuracy, keeping your accounting team happy.

- Logistics planning seamlessly integrates, eliminating manual entries, spreadsheets, and paper shuffling.

- Plus, we handle your industry-specific needs like grading, analysis, and quality testing, all in one place.

- This comprehensive solution provides confidence that your inventory is secure and accounted for.

Controller / Accountant

/ CFO / Bookkeeper

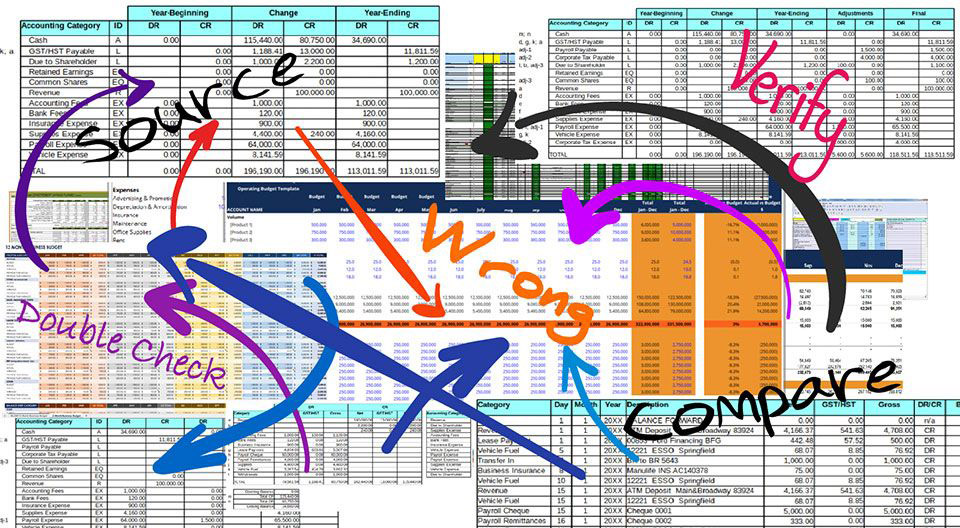

- Struggling with fast monthly closes or tired of generating inconsistent, unusable financial reports?

- NewBOS resolves this by integrating fully contracts, logistics, inventory, AR, AP, and the general ledger.

- Gone are disconnected departments and unnecessary spreadsheets, creating disconnected silos of information.

- With our automated auto-cost system you create "detailed accruals" to make every shipment complete, every day.

- Our "Big Picture PowerGRID" allows instant review of finances both daily and years past in a single place.

- Track profits per commodity, per trader, per customer or shipment effortlessly.

- NewBOS will help you meet your reporting demands from your bank, lender, CPA/CA, and owners.

- Simplify your financial life with NewBOS and feel free to ask us any accounting questions.

- Let's see how our industry experience and expertise can help your accounting team be even more successful.

NewBOS will absolutely help your company do more with less and make more with less.

Solution by Your Goals & Needs

Better Control, Less Risk

done efficiently and quickly.

- NewBOS is absolutely control focused, giving you full control of cash flow, trading risk, banking, AR collections, and inventory.

- Control to NewBOS means detailed daily profit visibility combined with proactive position management, thus losses are minimized, and decision-making is optimized.

- Fully integrating contracts, inventory, and logistics enhances your operational power by staying in control of each load.

- Compliance seamlessly monitors and manages your external risks, while integrating with email and auto locks to prevent losses.

- Our clients are empowered with maximum control to focus on increasing your capacity to make more profits with less risk.

NO Spreadsheets

NO disconnected data.

- NewBOS helps eliminate spreadsheets with PowerGRIDS, combining the efficiency of spreadsheets and seamless integration with your NewBOS data.

- PowerGRIDS fully empowers your team to organize, summarize, and export data, enhancing productivity and value.

- Dynamic formatting instantly and effortlessly transforms data into value to satisfy your different audiences and needs.

- Sharing information is streamlined with common formats (xlsx, csv, pdf), so making reports requires no additional effort.

- Say goodbye to tech dependency and hello to unparalleled control and efficiency with PowerGRIDS—a game-changer for you and your data.

Remove wasteful resources,

remove duplication and stress.

- NewBOS helps create efficient workflows by helping users identify and address inefficiencies, removing any and all wasteful efforts.

- We focus on providing your team with tools, techniques, and training to foster a proactive mindset, prompting the crucial question, "Is there a better way?"

- Our experts specialize in finding or crafting optimal solutions, ensuring tasks are performed once and only once, even if that means changing our software to help.

- By seamlessly integrating all aspects of your business from trading to accounting, NewBOS eliminates "silo" efforts and promotes collaborative value-building teamwork.

- Each team member builds upon the work of the previous, driving accurate and timely financial outcomes, the ultimate goal.

- With our robust data import/export capabilities, NewBOS streamlines all processes, minimizing manual data entry and maximizing efficiency.

- Our culture is clear: reuse existing data, leverage collective efforts, and continuously optimize workflows for peak productivity.

Team growth using

best practices, don't reinvent.

- NewBOS includes decades of industry best practices saving your team time and money by not reinventing solutions.

- Working with generic software, consultants, and trainers from outside your industry will absolutely add frustration, costs, and delays.

- Your team benefits from the collective wisdom of hundreds of industry specific companies, built directly into NewBOS, and our training systems.

- Our TrainingBOS courses include learning games which enhance comprehension and retention. Our content includes industry knowledge, technology hacks, best practices, as well as NewBOS software expertise, boosting your team's confidence and productivity.

- Comprehensive onsite and remote training packages are available and are recorded to build up your own company's learning assets.

- Our goal is your team's independence and capacity to handle and control your business and growth effectively.

- Additionally, we focus on using simple yet effective tools like checklists, task lists, and cross-training which are all proven to enhance your team's success and reduce your risks.

37 year's experience built into our products, you benefit by removing the guesswork.

Solution by Product

The ultimate goal of NewBOS is owners have more time to enjoy their life, play more golf, and have more fun without the stress related to growing or not feeling in control.

Today, the world wants to reduce a system's capacity to 3-4 letters, like ERP, CRM, TMS, or CTRM, but that creates confusion for you when a system, such as NewBOS, has all these things combined into a single unified platform.

NewBOS, along with our other suite of tools, creates a fully integrated eco system for your team that starts with contracting and risk management, through logistics and ultimately creating detailed and timely financial statements. Also add in full inventory and warehouse control, document management and everything in between and you can see why NewBOS doesn't fit into any single 3 letter acronym box.

NewBOS™ is designed to work all aspects of this industry, from simple direct-ship commodity merchandisers all the way to complex multi-state, multi-national animal/pet food manufacturers.

As you can see, there is so much to show you. A conversation is truly the best way to demonstrate NewBOS's capacity to help your company and team be even more successful.

MODULES:

Too many modules to list here...

NewBOS accepts that challenge continuously adding technology to automate or improve processes that allow your existing team to be massively more productive, more efficient, and more helpful.

The goal for your team continues to keep your growers, customers, vendors, and transportation resources happy. That's still a job for a skilled human, especially one that is empowered with the industry's best tools.

TrainingBOS focuses on your existing team to help them grow with your company however possible. We can't predict the future, but we can prepare your team for that future.

Deploying training is done easily through our TrainingBOS Web Course. TrainingBOS tracks and manages each team member's progress through the learning process.

Having fully resusable training materials supports the "real" human learning process. We also create a PLAY/SANDBOX version allowing your team to experience NewBOS's tools without fear or concern.

Buying software is one of the biggest decisions your company will make, but USING the software effectively right out of the box is the most valuable strategic plan your company must also make. Everyone has heard of the "failed" installation of new software by your competitors. That usually happens when expert training systems are not deployed effectively to assure your teams success.

Duplicating your Best Employee! We believe that each of your current team members possesses some skills and knowledge about how best to do his or her job, how to prevent problems, and ultimately how best to save and make the company money. We push the entire team operate at "best" members levels.

CLASSES:

- NewBOS Skills Foundation

- Accounting Foundation

- Logistics Foundation

- Trading Foundation

- Technology Foundation

- Controller Certification

- and more...

Please think of your inventory as cash that is controlled by a bank, except you are the bank, and ControlBOS is the software making sure every pound in and every pound out is tracked, just like your bank tracks your money.

ControlBOS also allows you to manage multiple owners inside of a single facility as is often the case.

EveryWEIGH is an NTEP certified scale management system designed for people controlling access to your facilities. These are the people physically touching the product from arrival to departure and everything in between.

ControlBOS/EveryWEIGH are tightly integrated with NewBOS for accounting and control purposes, we also allow your facility team to track what is "ACTUALLY" happening. This gives you the most accurate realistic insights into actual control and management issues, normally lost with standard ERP solutions.

WarehouseBOS is another module focused on tracking palleted and packaged products within a warehouse. This includes barcoded inventory, quick take physical audits, and most important keeping inventory fresh and organized to reduce waste and mark downs on your inventory.

Lot Tracking in real time yet another complex and demanding requirement for your physical facilities. ControlBOS allows for complete forward and backwards lot auditing to make sure you are ready for mock and real recall risks.

All your auditing for compliance, organic or other certifications requires you to have real time and accurate lot audit systems. With ControlBOS you can check that box as "approved."

We look forward to hearing your challenges and applying our decades of experience in inventory control to help you sleep better at night with ControlBOS.

MODULES:

- EveryWEIGH, NTEP Scale Control, for Truck, Rail, Totes...

- YardBOS, Visual map of live inventory

- WarehouseBOS, Manufacturing & Toted, Palleted Inventory

- LotBOS, Lot tracking full forward & reverse auditing

PaperBOS is the solution in every conceivable way.

PaperBOS is an extremely smart and automated Document Automation System (DAS) designed specifically for commodity and feed-related businesses. An example is some of your customers want both Origin and Destination scale tickets with their invoice, some don't? PaperBOS understands that need, along with countless other industry demands.

With PaperBOS, you can send contracts, invoice packages, and payment notices via email or printed for US mail, because not everyone outside your company is ready for paperless, this flexibility keeps your growers, truckers, and customers all very happy.

Streamline your invoicing process and reduce the time it takes to invoice from days to minutes after shipment delivery. Because PaperBOS fully integrates with EveryWEIGH, our scale system, and TruckBOS our driver mobile app, the delays and waste of handling paperwork disappear, and your team's efficiency increases massively.

Automate your daily document handling with PaperBOS's AI and OCR technology. This quickly reduces manual steps and workload for your team.

With reduced invoicing times, PaperBOS will pay for itself, by reducing the real costs of interest, handling, mailing, filing, searching, and storing paper.

By implementing PaperBOS, you will reduce paperwork, increase productivity, and enhance profitability.

MODULES:

- Explorer, Anyone can help customers, grab a copy of a scale ticket.

- Matcher, Intelligently match your NewBOS accounting transactions with document images.

- Packager, Automatically package primary and supporting documents into PDF's and email them.

- Smarter, teach PaperBOS the rules to keep each customer, grower, and trucker happy.

- the Vault, a simple place on your desktop to drop images from email, or other sources efficiently.

NewBOS has developed a secure and comprehensive mobile platform suite that enables your team and external parties to access and update information your NewBOS system, eliminating waste and duplicated efforts.

Our clients face unique challenges when it comes to deploying mobile technology on the road and in rural areas of our country.

That's why we've created the MobileBOS platform, which offers both online and offline functionality.

This is crucial in the agricultural industry, where many facilities and areas lack reliable internet access or cell service. Our mobile app development approach ensures a robust and reliable experience for users, including forklift operators, truck drivers, and salespeople working in remote areas.

Our suite of mobile applications includes TruckBOS, SalesBOS, WarehouseBOS, and CrmBOS (Farm & Sales). Each app is designed to increase productivity of specific team members.

As we continue to develop and deploy new tools and modules, they will become part of our comprehensive suite of mobile applications.

Our goal of creating best of breed apps, so you don't have to reinvent anything.

We're always learning and excited to hear your visions, needs, and goals for mobile applications that will benefit your team, customers, and growers.

MODULES:

- SalesBOS, fully empower your field sales team and client confidence.

- CrmBOS, (Farm Edition), Order and manage agronomy and fertilizer related business needs.

- CrmBOS, (Sales Edition), Keep up to date on all contracts, logistics, and customer information.

- TruckBOS, Empower drivers (internal and external) with LIVE LOAD access, and Proof Of Delivery for you.

- MobileBOS, platform to help you design what matters most to you.

Successful projects include:

Delivery Driver Portal: Get delivery details instantly and provide LIVE updates on delivery progress, keeping everyone updated.

Customer Portal: Customers can access their open contracts, active shipments, and payment history on a single platform.

Dispatcher Portal: External transportation companies can view assigned loads and dispatch with driver assignments, automatically uploading to individual drivers using the TruckBOS mobile app.

By working with the WebBOS platform and team, businesses will solve problems and deploy solutions that benefit both the company and its partners.

With WebBOS, make work easier and faster by securely connecting your business partners directly to your internal team. The platform enables our clients to streamline operations, reduce waste, and improve communication, making everyone's life better.

MODULES:

- WebBOS Customer Portal (Sales - Shipments- AR - Cash)

- WebBOS Dispatcher (Load Schedule - Driver Assignments)

- WebBOS Supplier (Purchases - Shipments - AP - Payments)

- WebBOS Custom Solutions, what do you need to be more successful?

Start your journey to a better life today with NewBOS,

it really is as simple as 1,2,3

Call/click our phone number above and

connect with a real human who genuinely cares.

Step- 1 Schedule a Demo

After listening to you and based upon your specific industry and goals, we will customize your demonstration.

Also, we will record it, so you can replay it and share it.

Step - 2 Implement Your Custom Plan

We guarantee a successful implementation and accurate data conversion. Through our decades of success, systematic practice trials and comprehensive training programs we know your team will have the skills and confidence to succeed.

Step - 3 Enjoy a Better Life

NewBOS will be there by your side every hour and every day to help you. We push ourselves and your team to get the most out of your decision and investment in NewBOS software. This is a life long relationship that starts and finishes with mutual respect, caring and trust. Just ask our clients who have been with us for over 37 years, without missing a single day.

OUR SINCERE OFFER OF HELP, PLEASE READ,

REGARDLESS OF WHAT SYSTEM YOU SELECT:

So, what are the hidden costs of making a wrong software choice and how can you prevent it?

Your team and your company deserve to make this critical investment and huge decision correctly the first, and only time. It can mean the difference between success and failure in many cases.

Your team also deserves to have the best training, best support, and the true benefits of working side by side with industry experts, helping you implement and create your company's personalized best practices.

COSTS AND RISKS TO CONSIDER

Don't get trapped wasting time and energy with your team teaching high priced "Management Consultants" how your business works. This model is focused upon your "dreaming" to get a fully customized system, but instead they use it to charge you unlimited amounts of consulting fees, with the single goal of never finishing. Obviously, that is the opposite of what you need or want.

Buying non-industry specific (generic) solutions with the promise that they can customize it for you is nearly impossible, and usually just a "scheme" to get you committed and then start charging you for a lifetime of consulting and services. Never really focused upon the actual goal of your success or benefit of the software purchase.

We have heard so many horror stories of consultants working with your team for a few months, then that person is "transferred/promoted" away to another project, so you will get to start all over again, and again, and again. Yes, you got it, forever increasing your consulting bills.

When choosing company's software will obviouisly consider all the actual quoted costs, but also the hidden costs in time, stress, and strain on your employees. Frustrations from failures and spending time in unlimited meetings with new consultants will build up negative pressure in your team, that often goes unspoken. These pressures ultimately result in added risks to the project, and worst case turn over of your team who simply gets tired of it all.

NewBOS and other industry focused solutions have all that expertise built into the software solution, from day 1, and are knowledgable in the industry. That creates a massive reduction in the time and costs it will take for you to benefit from the investment in software that you are considering.

BIG QUESTIONS

- Can you afford to partner with a software or consulting company that doesn't understand your industries and your business models?

- Can you afford to work with a company that isn't willing to change the software to make it better every day? (Some vendors will not modify their system or they do not have a programming team available).

- Can you afford to pay unlimited consulting bills even if they don't produce results?

- Does your team have time, energy and passion to do this process more than once, if failure occurs when going with generic "big named" softwares?

- Do you feel comfortable paying money up front, working with open-ended budgets, or not having a guarantee of success as part of the understanding of value?

PREVENT MAKING A BIG MISTAKE

Here are some simple rules you can follow to make sure you select and work with the right software partner.

If the person selling you software can't or won't accept most of these rules, you should think more than twice about selecting them as a technology partner or software provider.

13 EASY & POWERFUL WAYS TO PREVENT YOUR COMPANY

FROM BUYING THE WRONG SOFTWARE, FROM THE WRONG COMPANY!

#1. RECORD EVERYTHING:

Relationship built on accountability and trust

- Recording all interactions with vendors ensures accountability. This prevents companies from making unsubstantiated claims and holds them to their promises, fostering transparency and trust.

- Recording conversations and requests shows respect for the users' time and efforts. Capturing their needs and feedback accurately avoids repeatedly asking the same questions, which can frustrate users.

- Recording meetings and demonstrations streamlines communication and collaboration within teams. A clear record allows teams to refer back to discussions, reducing the need for repetitive clarification and ensuring everyone is on the same page.

- Recording interactions ensures that all vendors receive the same information, making it easier to compare their responses and performance. This consistency helps in evaluating which vendor best meets the company's needs based on a fair and equal assessment.

- Adopting a "record once, use many times" approach significantly enhances productivity. With recorded materials, teams can focus on more critical tasks instead of redundant meetings, ultimately improving efficiency in an already busy work environment.

#2. DEMAND EXACTING DEMONSTRATIONS: When you ask about a feature, don't let them just say "Yes", make sure they are willing to show you, in full detail how it is done, and how fast you can do it? Remember just because they say yes, doesn't mean that it won't take 5 minutes to do something that should take 15 seconds. (These are real examples by the way). Also, try to never use the language, "I assume it will...". It is never good to assume, and when doing so, it leaves gaps in understanding, and definately room for missed critical features. Just because a system has been in the industry for decades, or has been doing accounting for decades doesn't mean they do things as you need. The simple topic of how detailed accruals are made (not cost allocations). This is often an assumption made with systems and a negative surprise results when there isn't fully automated accruals as part of a system. Unfortunately software is sold based upon too many assumptions, and while it is nearly impossible to get 100% guarantee on everything, the less assumptions made the better. Any good software salesperson will be patient and allow you to request demonstrations of any and everything that's important without relying upon assumptions.

#3. INTEGRATION-RESPONSIBILITY: Can they show you full integrations between modules or are they saying "These systems should be able to integrate?" Are different modules being glued together from different vendors. If so, there will be no single point of responsibility and you will be spending the rest of your life in meetings trying to get them to take responsibilty and solve your problems? Many generic software companies like to use the phrase "oh you can simply" integrate with these 5 other vendor's tools. What they don't mention, is rarely is it that easy or smooth, and usually it can also be expensive in time, money and frustration. Of course the concept of 2 computer systems talking is easy in concept, but when the actual requirements of moving the data, connecting transactions with master table data, and keeping changes and updates syncronized between two systems is a requirement, the whole game changes. Finding a software company that has made the effort to develop a single, integrated solution to prevent getting too many chef's in the kitchen did so because of these very challenges. Make sure any proposed integrations are verified and confirmed to have worked, and get proof that the projects finished on time and on budget. Those are often the unspoken facts of the reality after the simple promise is made. If this is part of your project require fixed budgets, and fixed time frames, and do not pay in full until the project meets or exceeds your expectations.

#4. NO LONG-TERM CONTRACTS: Make sure you do not have to sign any LONG-TERM CONTRACTS? Often times they trick you by offering great discounts for 5 or 7 year contracts, only to find out you can't cancel the contracts even if they do not perform. There is no need for a long-term contract with NewBOS because our contract is keeping you happy. Our only goal is to earn your business every month with competent, caring and passionate support for your success.

#5. REQUIRE A GUARANTEE: Make sure your success is guaranteed or you would get your "software" fees refunded. While there may be some hard costs, the "software or service" fees should not be kept by a supplier who is not successful. If they take your money they should be 99.99% sure your installation is going to be a success. As the old saying goes, "Put their money where their mouth is!

#6. DON'T LOSE CHANGES: If you select a generic system, just know that you will have a huge amount of work ahead of you and the team to get it "CUSTOMIZED" to your industry. And most times it won't work nearly as effectively as an industry specific solution. But just make sure you control the money for these customizations. Make sure you have access to the changes because you may have to change "consultants" and you need to keep control of your invested changes.

#7. WORK DIRECTLY-NO MIDDLEMEN: Make sure you have direct access to the COMPANY WHO MAKES THE SOFTWARE. Many of the big consulting firms are just "facades" over the actual company who writes and supports the software. That means every problem, change, or request you have, must go through layers and layers of "billable" resources for each company that get's involved. Of course this model is great for the consulting revenue generation, but not so good for your frustrated users who need actual help. Make sure you can call someone in management with a single call to get help, when you need it. With NewBOS you can speak directly with any of our partners or programmers if you need to, and we don't make you beg or bargin with us to do so. Just a single call, and you can speak with anyone in our company.

#8. WORK WITH HUMANS-NOT BOTS OR EMAILS: Make sure the company proudly provides you their phone number, and make sure they can call you back directly. This is a new addition to the list, because the NEW-MODERN approach to customer service is NO PHONE NUMBER FOR YOU!, just email support, making it impossible to get a problem solved quickly. They expect you to fill out a form online, press send, then wait.. and pray that someone is maybe going to email you back, usually with a question. We fully understand the reason for this and in most cases this can be "fine" way to provide support. But when something is really important, critical or stressful, your provider should provide you a phone number to call which is answered promptly by a human. Someone who can hear you, and get you immediately to someone that can help.

#9. OWNERS MAKE DECISION, GET INVOLVED: Don't just let the youngest team members, or any single individual take the responsibility for selecting your software. Sometimes a company hires a new person or a consultant to help them purchase software, only to have that person quit, retire during or after the decision is made. Then you, the OWNERS, are stuck with that decision. While all those team members are great contributors to a decision of this magnitude, only the OWNERS of the company should make the final decision. In the end it is a long-term relationship with the software company and your company. Don't make this only about TECHNOLOGY or only if the young generation thinks the product is pretty, so they like it. This is a decision to run your company more profitably in the end. The decision is how to make more sales with less overhead, less risk, and less waste on fighting with technology. Those are decisions OWNERS MAKE, not employees or consultants.

#10. SALES, REVENUE, TRADERS, LOGSITICS FIRST: Buy the BEST system that runs your company's ability to grow top line profits, first. Many times the accounting teams or IT teams feel they are the MOST IMPORTANT people in the software decision, but those departments are not responsible for generating income and profits. We are not trying to be rude, but often time we see companies select a software package that makes the accounting team happy, but makes the sales and logistics teams suffer, and usually become less effective and efficent. Accounting is actually very easy when done correctly. Accounting is standardized and if all the debits and credits are generated quickly, accurately and in many cases automatically the accounting department can make the best of it (We are not trying to offend, but rather focus your decision on the REVENUE side of the business). We understand that some BUSINESS FOCUSED SYSTEMS are not good at accounting (in fact down right wrong), so please look for something like NewBOS that knows accounting as well as it knows the trading, sales and logistics. Then you get a system that truly pushes profits and success, yes the best of both worlds.

#11. OPEN TO IMPROVEMENTS: Only work with a company that will take your ideas and suggestions seriously and will consider adding those changes to their system. Work with a team that is passionate about creating a "best of industry" solution, a team that's always learning and growing based upon actual users "great ideas". We have found that new users always have new ideas, some which really can help all users going forward. You might ask, "How many full time developers do you have on your team?" compare that answer to the number of salespeople and number of business consultants. Usually the company with more developers is focused on improving the system, the one with more salespeople is more focused on selling the system. Over the next 10+ years of using these systems, you will always be happier with the development focused team, software, and company.

#12. CUTE, FUN, PRETTY vs PRODUCTIVE: When looking at software for the first time it can be extremely overwhelming, so a lot of software companies have "over simplified" software to make it less intimidating to a "new user" aka the buyer. Please notice that in most demonstrations you will see the salesperson using the software with ONLY MOUSE CLICKS, and saying things like "just click the date" to select a date. This is all fine and good for the first 15 days, until you expect to see productivity improvements from your team over time, meaning after the first 90 days all the "NEWBIES" should become experienced users. After the first year everyone should have moved to master level skills for the area they use daily. Unfortunately most "modern" interfaces (most browser based software) doesn't allow improvements in productivity or performance. They are cute, simple and very mousy click, click, click focused (this sells software). This interface design, actually holds a user back, as they can't improve because it's a single point/click, and it requires the "mouse" to be moved with a hand, taking the actual fingers away from their work surface (called a keyboard). Again, beware, during a demo (aka not working for real productivity), it is cute, fun, friendly and seemingly easy, so any "_ _ _ _ " can use it, but that interface will become an anchor, if you can't fully use keyboards and shortcuts. Just google it. and find that pure mouse interfaces are like only 25% as efficent as keyboard focused interfaces. Remember this is a productivity tool you are investing, not a toy. Make sure the tool you invest in offers the combination or the best of both worlds, so your power users can really become powerful, instead of handcuffed by simplicity.

#13. DON'T START TOO EARLY or TOO LATE: The huge project of changing your company and team to new tools is one that requires confidence and humility. That means, it's better to "slow" down in order to speed up. If the system you are moving to has not been tested completely, or the users are not feeling "pre-trained" enough, you are better to delay a jump decision, rather than jump off without the safety and confidence of a near guaranteed success. On the otherhand, you can't wait forever to go. If Go-Live date continues to get pushed out further and further it maybe a sign you have selected the wrong system or wrong partner for your software decision. We find that about 15% of the GO-LIVE process is literally reacting, in real-time. with needs, problems, or changes that need to be addressed. While in a perfect world, all these would be discovered in the testing and sandbox phases of the project, you must also make sure your partner can move quickly in resolving mission critical changes during the GO-LIVE. Of course "live" changes must strike a delicate balance of risk verses solution. However, the best way to assure success is making sure you don't pay 100% for services and software before you are LIVE AND HAPPY with the actual software in your production environment. Any good software company should be able to afford you this time, their new and valued long-term customer, to be confident it's going to be okay.

NewBOS has always been available for our customers 24/7. And in 37 years we have never had a customer abuse the freedom or right to be able to call us for help. Why would a company feel that hiding from their customers is healthy or smart? We are here for you and you are here for us, that's what's called a WIN WIN. Only work with a company that has this approach, because the alternative will simply create frustration, waste, and in the end, a loss of valuable time and money for your company.

NewBOS is the full solution for your company's industry specific operating challenges. NewBOS is an integrated system featuring contract management, logistics execution, inventory control, financial reporting, ... and everything in between. It's hard enough to run a successful business.

Make the right decision, the first time and don't let your main software get in the way of your success.

Jeff White

Founder & Member